Accurate repeatable costing

Costing a bespoke furniture is a complicated task that involves complex spreadsheets & hours of work. To save this time & effort, often businesses end up quotating based on per sqft rate without knowing whether they would be able to maintain their profit margins at the quoted rate.

We make all of this as simple as a click of a button for you. Based on your cutting list of the furniture we figure out how much material you would require. From the master price list, we calculate the cost of the smallest to largest material, add labour costs, freight, wastage and provide you with the most accurate cost of the bespoke furniture you could possible get!

The standard practice followed by small & medium busineses for costing a bespoke furniture is simplistic & unscientific. We simply quote based on the sqft rate of the outer dimensions of the furniture. Sounds familiar? But does this give you any confidence whether your margins will be protected? No, because when it comes to bespoke furniture, each and every piece is unique in its own ways and small changes in materials or requirements can affect the pricing considerably.

A lot of SMEs have solved this be developing complex spreadsheets where they enter their rough cutting lists, hardware, and other materials to get the material cost, total sqft and calculate labor based on that. But how complex are those spreadsheets? Have you thought how many hours you spend maintaining them with ever changing prices, requirements and cutting List. Furthermore, if there is one mistake in the spreadsheet, you completely lose confidence in your estimate, and then ultimately fallback to lumpsump sqft based pricing!

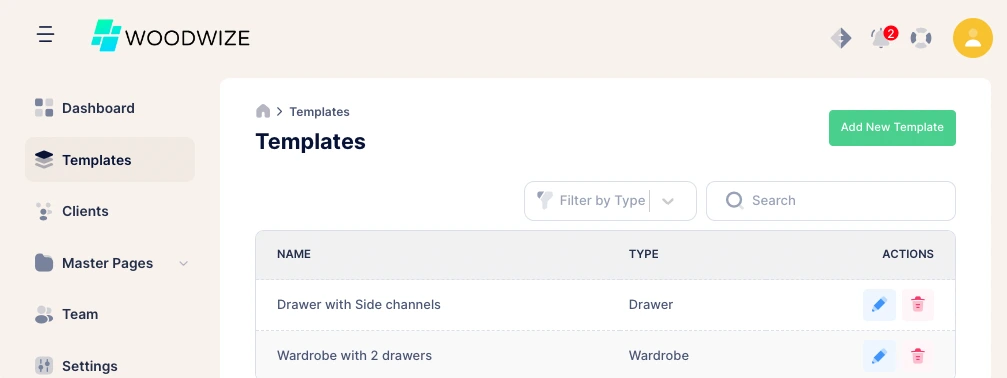

We observed these problems, studied the spreadsheets in details and came up with a solution that is simple and intuitive! With Woodwize, we have built a template based cutting lists. Here is how it works:

Reusable templates for costing

Costing can be a breeze with templates

For every unique furniture, you need to create your cutting list only once and then save it as a template. In future, quickly use the template, add dimensions and your cutting list is ready.

- Save your cutting list as template

- Use templates as building blocks

- Templates can have other templates inside them

- Just enter the dimensions and get the costs